I. Overview of plastic pipes

As an indispensable material in modern construction and industry, plastic pipes have gradually replaced traditional metal pipes and become the mainstream choice due to their advantages such as light weight, corrosion resistance, easy installation and high cost-effectiveness. With the advancement of materials science, the types of plastic pipes have been continuously enriched, the performance has been continuously improved, and the application areas have also expanded from the initial water supply and drainage systems to gas transmission, floor heating systems, industrial pipelines and other professional fields. This article will systematically introduce the characteristics, classification and application of various types of plastic pipes in different scenarios, and provide professional reference for engineering design and home decoration material selection.

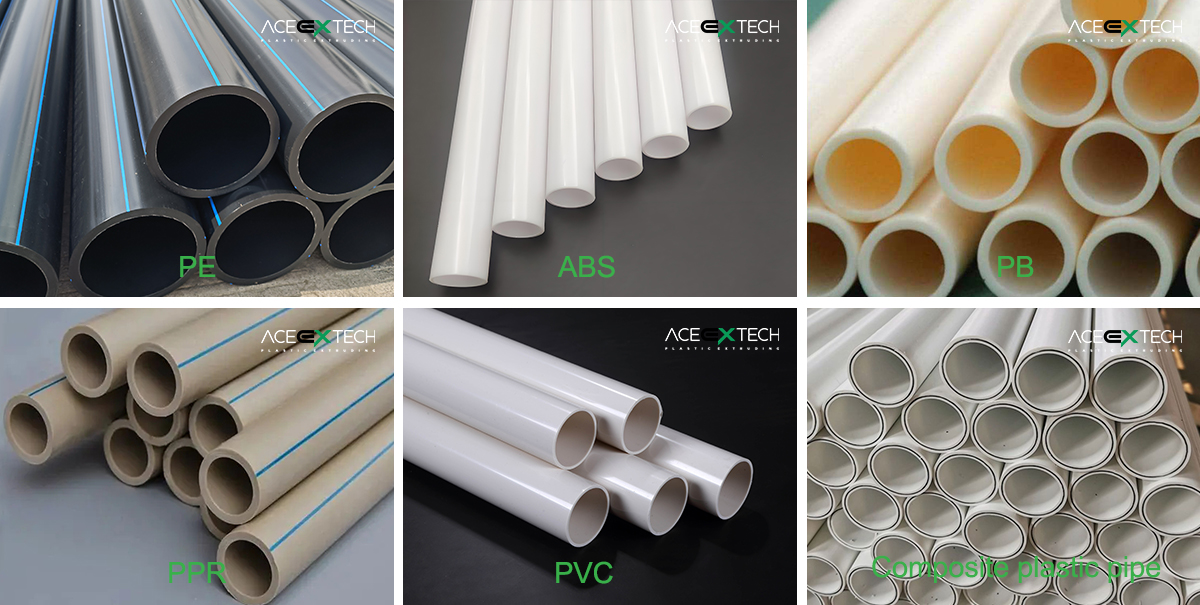

II. Main categories and characteristics of plastic pipes

1. PVC pipes (polyvinyl chloride pipes)

PVC pipes are one of the earliest plastic pipes to achieve industrial production, which can be divided into two main types: hard PVC-U pipes and soft PVC pipes. Its notable features include:

- Excellent corrosion resistance, can resist the erosion of most acids, alkalis and salts

- High rigidity, strong resistance to external pressure

- Good flame retardant performance, oxygen index ≥45

- Service life of more than 50 years

Common specifications: diameter ranges from Φ20mm to Φ630mm, and the pressure level is generally 0.6MPa-1.6MPa.

2. PE pipe (polyethylene pipe)

PE pipe can be divided into:

- HDPE (high-density polyethylene pipe)

- MDPE (medium-density polyethylene pipe)

- LDPE (low-density polyethylene pipe)

Outstanding features:

- Excellent flexibility and impact resistance

- Good low-temperature performance, still flexible at -60℃

- Excellent hygienic performance, can be used for drinking water transportation

- Unique welding connection method to achieve leak-free joints

Pressure level: PN6-PN16 series, with a maximum diameter of Φ1600mm.

3. PPR pipe (random copolymer polypropylene pipe)

PPR pipe is a new type of pipe that has developed rapidly in recent years. Its characteristics include:

- Good high temperature resistance, long-term use temperature can reach 70℃

- Hot melt connection to form an integrated pipeline system

- Smooth inner wall, small water flow resistance

- Non-toxic and hygienic, in line with drinking water standards

Common specifications: outer diameter Φ20mm-Φ110mm, divided into four series of S5, S4, S3.2, and S2.5 according to wall thickness

4. PB pipe (polybutylene pipe)

PB pipe is known as the "gold of plastics". Its characteristics include:

- Wide temperature resistance range (-30℃ to 110℃)

- Excellent creep resistance

- Good flexibility and can be coiled for construction

- Extremely high durability, with a service life of more than 50 years

5. ABS pipe (acrylonitrile-butadiene-styrene pipe)

Main features of ABS pipe:

- High mechanical strength and impact resistance

- Excellent chemical corrosion resistance

- Working temperature range -40℃ to 80℃

- High surface hardness and good wear resistance

6. Composite plastic pipe

Composite pipe combines the advantages of plastic and metal. The main types include:

- Aluminum-plastic composite pipe (PE-AL-PE)

- Steel-plastic composite pipe

- Glass fiber reinforced plastic sand-filled pipe

- Plastic steel winding drainage pipe

III. Typical application areas of various types of plastic pipes

1. Building water supply and drainage system

- PPR pipe: the first choice for building hot and cold water supply systems, especially suitable for household tap water pipes

- PVC-U pipe: the conventional choice for building drainage and rainwater systems, drainage risers for high-rise buildings

- HDPE pipe: underground water supply network, outdoor water supply system for residential areas

- ABS pipe: drainage system for high-rise buildings, especially suitable for places requiring high impact resistance

Selection suggestion: PPR pipes are preferred for indoor water supply, and PVC-U or ABS pipes are selected for drainage systems according to pressure requirements.

2. Heating and air-conditioning system

- PB pipe: high-end residential floor heating system, radiator connection pipe

- PE-X pipe: mainstream material for floor heating coils, excellent high temperature resistance

- PPR aluminum-plastic composite pipe: radiator connection pipe, both rigid and flexible

- PE-RT pipe: medium and low temperature radiant heating system, good thermal stability

Technical points: Floor heating system should choose pipes with high temperature resistance ≥95℃, and the working pressure should not be less than 0.8MPa.

3. Gas transmission system

- PE gas pipe: medium and low pressure urban gas pipeline network, divided into SDR11 and SDR17 series

- Steel-plastic composite pipe: high and medium pressure gas transmission, with the strength of metal pipe and the corrosion resistance of plastic pipe

Safety specification: Gas pipelines must use special PE100 gas pipes with yellow markings and comply with GB15558 standards.

4. Industrial pipeline applications

- PP pipe: corrosive media transportation in chemical enterprises, excellent acid and alkali resistance

- PVDF pipe: high-purity chemical transportation, ultrapure water system in semiconductor industry

- HDPE double-wall corrugated pipe: industrial wastewater discharge, municipal sewage pipe network

- FRP pipe: long-distance transportation of corrosive media in petroleum and chemical plant areas

5. Agricultural irrigation system

- LDPE drip irrigation pipe: precision irrigation system, high water saving efficiency

- HDPE agricultural pipe: main pipe for field irrigation, good UV resistance

- PVC farmland drainage pipe: underground drainage system, high cost-effectiveness

6. Special application scenarios

- MPP power pipe: cable protection sleeve, trenchless jacking construction

- Silicon core pipe: communication optical cable protection pipe, extremely low friction coefficient

- HDPE hollow wall winding pipe: large municipal drainage project, diameter up to 3m

IV. Plastic pipe selection guide

1. Key factors in selection

- Medium characteristics: consider the temperature and chemical properties (pH, alkalinity, etc.) of the transported liquid

- Working pressure: Select pipes with appropriate pressure levels according to the system design pressure

- Environmental conditions: UV resistance should be considered for outdoor use, and ring stiffness should be considered for buried pipes

- Hygiene requirements: Food-grade pipes that meet hygiene standards must be selected for drinking water systems

- Installation methods: Different connection methods such as hot melt, adhesive, and mechanical connection affect pipe selection

2. Cost-effectiveness analysis

| Pipe type | Initial cost | Service life | Maintenance cost |

| PVC-U | Low | 50 years | Low |

| PPR | Medium | 50 years | Very low |

| PE | Medium | 50 years | Low |

| PB | High | 50-70 years | Very low |

| Composite pipe | Higher | 50 years | Low |

V. Development trend of plastic pipe industry

1. High performance: Develop new plastic alloy pipes that are resistant to high temperature and high pressure

2. Green and environmental protection: Research and development of recyclable, low-energy eco-friendly pipes

3. Intelligence: Intelligent pipeline system with integrated sensors to monitor pipeline status in real time

4. Standardization: A global unified pipe standard system is gradually established

5. Construction innovation: Promotion and application of trenchless technology and 3D printing pipeline technology

Conclusion

The reasonable selection and application of plastic pipes are crucial to the quality of engineering construction. Understanding the characteristics and application scenarios of various types of pipes and scientifically selecting them according to specific project requirements can not only ensure system reliability but also maximize economic benefits. With technological advances, plastic pipes will inevitably replace traditional materials in more fields and provide safer, more environmentally friendly and economical pipeline solutions for modern engineering construction.